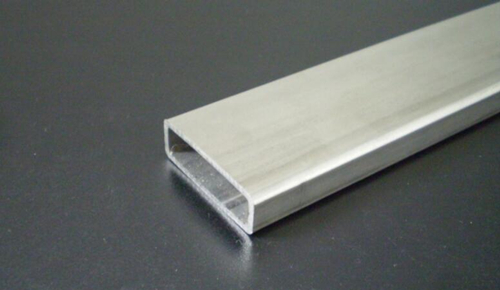

Welded Stainless Steel Rectangular Pipe

- Grade: 301, 304, 304L, 316, etc.

- Standard: ASTM, AITI, JIS, GB

- Wall Thickness: From 0.3 mm

Specifications of Stainless Steel Rectangular Pipes:

1. Standard: GB, ASTM, JIS, DIN

2. Grade: 201, 202, 301, 304, 304L, 304N, 310, 316, 316L, 321, 409L, 410, 430, 439L, 904L, etc

3. Outside Diameter: 20*10mm to 100*80mm

4. Wall Thickness: 0.3mm—3mm

5. Length: as demand

6. Surface finish: Polishing (180#,220#,240#,320#400#,600#), Hairline, acid pickled and so on

7. Applications: Frames, roll cages, truck racks, trailers, railings, etc.

8. Workability: Easy to Weld, Moderate Cutting, Forming and Machining.

9. Mechanical Properties: Brinell = 170, Tensile = 85,000 +/-, Yield = 34,000 +/-, Nonmagnetic

Manufacturing Process of Stainless Steel Pipes/Tubes:

The process commences with the formation of welded mother tube on the tube mill from imported and tested prime quality stainless steel strips. The latest TIG multi electrode welding technique is employed for superior weld quality and 100% Fusion, with argon purging, No filler metal added.

Packaging of Stainless Steel Tubes/Pipes:

Please don’t worry that our products are packed, stored, transported according to the international regulation. We do care about the quality of our products; even some little details are paid attention to.

We wrap the stainless steel products with anti-rust paper and steel rings to prevent damage. Identification labels are tagged according to standard specification or customer's instructions. Special packing is available as per customer's requirement.

Plus, our storage racks are made of wood. Other kinds of metals are settled in other places, far from the stainless steel. Any unwanted chemical reaction can be prevented.

CLICK HERE FOR PRICE

Clickhere

for

price